Промышленные услуги будут Versusgas

Обработка металлов на станках с ЧПУ

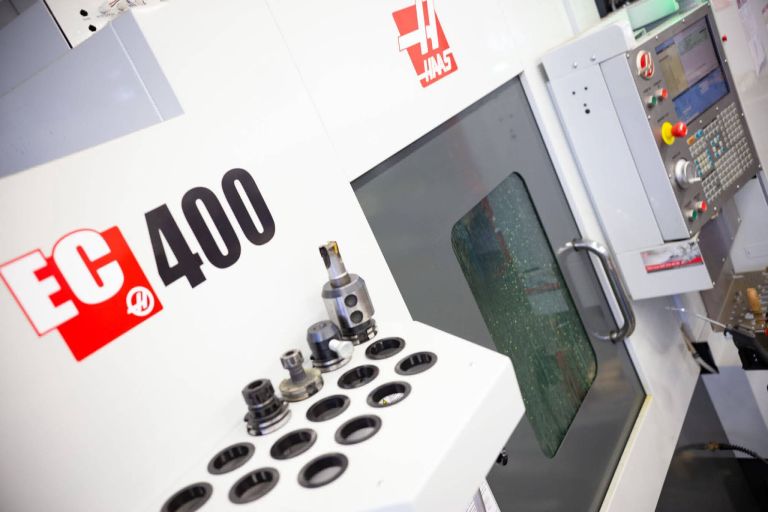

Мы специализируемся на обработке металлов на высококлассных 7-осевых обрабатывающих центрах, произведённых компанией HAAS. Эти устройства позволяют нам выполнять практически любые проекты с использованием различных сплавов черных и цветных металлов. Наш опытный персонал работает в полной среде проектирования CAD/CAM, что обеспечивает полный цикл удовлетворения запросов клиента — от оптимизации проекта до реализации готовой детали.

Наш отдел ЧПУ предлагает услуги по:

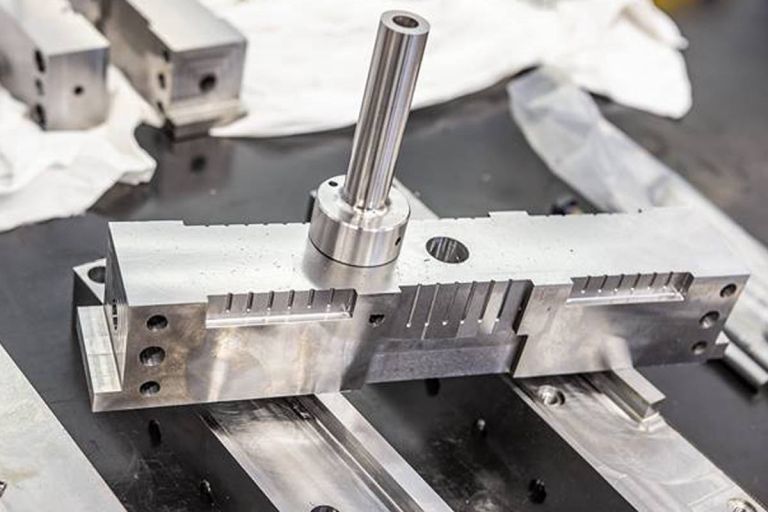

- Обработке плоских и фигурных поверхностей;

- Массовой обработке заготовок после предварительной подготовки инструмента;

- Изготовлению прототипных деталей.

Два наших обрабатывающих центра HAAS способны обрабатывать детали с максимальными размерами:

- 356 x 508 x 457 мм

- 508 x 508 x 600 мм

Мы специализируемся на подготовке форм для литья пластмасс под давлением, а также на крупносерийном производстве мелких деталей для автомобильной промышленности.

Дополнительное оборудование

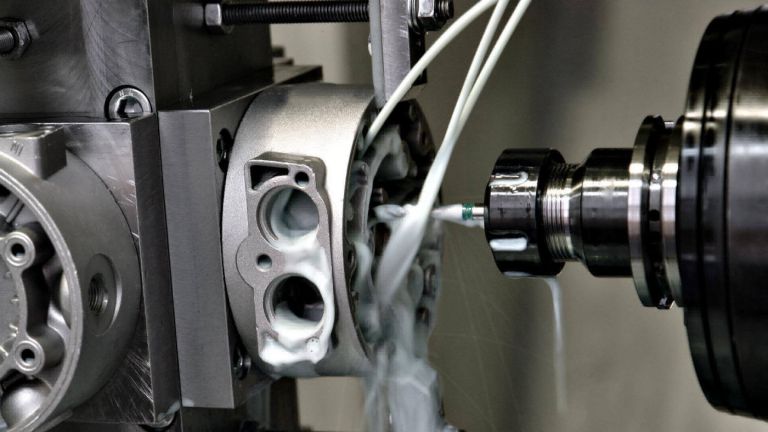

В дополнение к крупным обрабатывающим центрам у нас есть автоматические 3-осевые токарные станки, которые используются для производства мелких деталей со следующими возможностями:

- Одновременные операции точения и фрезерования;

- Нарезание конических, метрических, дюймовых, наружных, внутренних и трапецеидальных резьб;

- Обработка сложных деталей за один цикл;

- Максимальный диаметр обрабатываемого прутка: 32 мм (или квадрат с максимальной стороной 20 мм);

- Максимальная длина рабочей зоны: 229 мм;

- Возможность обработки пластиковых материалов, таких как POM, PA6, PEEK и других.

Литьё пластмасс под давлением

Промышленные услуги от Versusgas

Литьё пластмасс под давлением

Наше предприятие оснащено современным горизонтальным сварочным оборудованием, адаптированным под формы с холодным литниковым каналом, что позволяет обрабатывать широкий спектр термопластичных материалов. Эта полностью автоматизированная линия обеспечивает следующие процессы:

- Размораживание;

- Предварительный нагрев;

- Поддержание температуры.

Максимальные физические параметры форм:

- Ширина x длина x высота: 350 x 350 x 300 мм;

- Масса впрыска: до 140 г.

Мы предоставляем услуги по проектированию и изготовлению форм в соответствии с индивидуальными спецификациями заказчика, а также предлагаем консультации и поддержку на всех этапах производственного процесса.

Для получения дополнительной информации обращайтесь: info@versusgas.com

Промышленные услуги от Versusgas

Обработка электроники SMT/THT

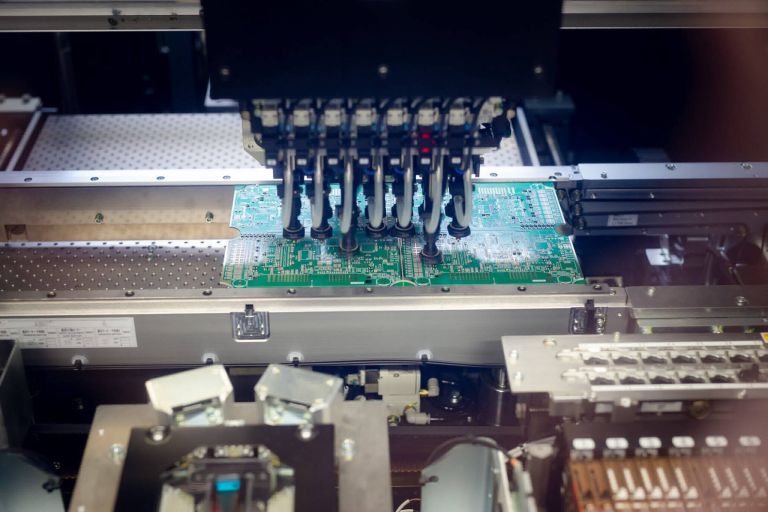

Обработка электроники SMT/THT

Наша современная и полностью автоматизированная линия для производства SMT позволяет нашим клиентам выполнять крупномасштабное производство и проверку готовых к использованию электронных схем. Мы используем передовое оборудование от Panasonic, Ersa, Vi Technology и I-Con, чтобы соответствовать следующим требованиям:

- Установка компонентов размером от 0,4 мм x 0,2 мм (01005 или 0402 метрический) до 14×14 мм;

- Максимальная площадь панели печатной платы: 510 x 460 мм;

- Максимальная высота компонентов: 28 мм;

- Максимальный размер разъемов: 120 x 90 мм;

- Двусторонний монтаж;

- Селективная пайка волной;

- Установка BGA с шагом до 0,5 мм.

Ключевые показатели производительности линии:

- Скорость размещения компонентов (по стандарту IPC9850): более 16 500 шт./ч;

- Точность установки с лазерным распознаванием: менее ±55 мкм;

- Точность расположения с оптическим распознаванием: менее ±40 мкм.

Преимущества нашей производственной линии:

Производственный процесс соответствует стандарту ISO 16949 – элементы проходят через всю линию без вмешательства человека. Для обеспечения максимальной надежности и эффективности продукции в процесс включены ключевые элементы:

- Высший стандарт защиты от электростатического разряда (ESD);

- Автоматическая встроенная оптическая инспекция (Vi Technology);

- Нанесение защитного покрытия после сборки печатной платы.

Наш отдел электроники оснащен оборудованием для анализа и измерения цифровых и смешанных сигналов, что позволяет проводить оценку схем. Мы оказываем помощь клиентам на каждом этапе разработки, оценки и производства электронных схем.

Для получения дополнительной информации обращайтесь: info@versusgas.com

Промышленные услуги

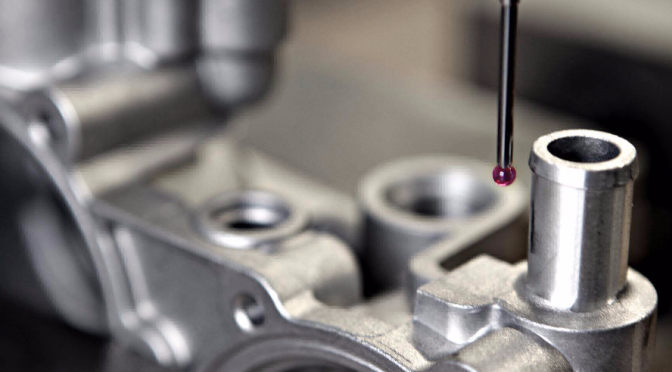

3D Сканирование

В нашем распоряжении находится профессиональный 3D-сканер Nikon для контактных координатных измерений с точностью до микрометра.

Это промышленная, стационарная система, предназначенная для работы в контролируемых условиях. Большие рабочие объемы в сочетании с высокой точностью и повторяемостью результатов открывают новые возможности для надежного воспроизведения 3D-моделей, используемых в промышленности.

Преимущества контактной измерительной машины:

- Исключительная точность измерений: 0,001 мм;

- Рабочие размеры (Ш x В x Д): 700 x 500 x 500 мм;

- Существенное сокращение времени измерения каждого элемента;

- Унификация результатов измерений множества элементов;

- Устранение неопределенности измерений, вызванной использованием разных инструментов для одной детали;

- Прямой рабочий процесс: объект 3D → файл CAD/CAM.

Для получения дополнительной информации обращайтесь: info@versusgas.com